If you've ever struggled with warping, cracking, or inconsistent layer adhesion in 3D printing, the culprit may not be your filament or settings - but rather your heated print bed. Traditional single-zone heating systems often fail to maintain uniform temperature across the entire build surface, leading to print failures and wasted material. This is where multi-zone silicone heaters come into play.

The Problem with Single-Zone Heating

Most standard heated beds consist of an aluminum plate paired with a single heating element. While simple in design, this setup has a critical flaw: heat loss from the center toward the edges. It's not uncommon to observe a temperature difference of 5-15°C between the center and the corners of the build plate. The larger the bed, the more pronounced this issue becomes.

In 3D printing, bed adhesion relies heavily on maintaining a consistent temperature at or above the material's glass transition temperature. For example: PLA requires around 50-60°C, ABS needs 90-110°C and so on.

When the edges are cooler, the outer areas of your print may not adhere properly. As the material cools and contracts, it can lift from the bed - a phenomenon known as warping. This is especially noticeable with large prints, where sections outside the central heated zone may not stick at all, leading to layer separation or complete failure.

How Multi-Zone Heating Solves the Problem

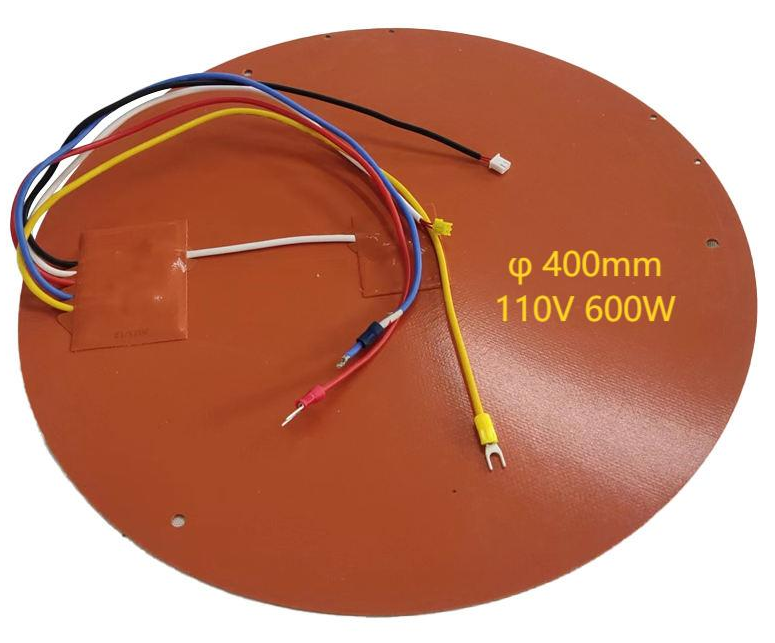

A dual-zone silicone heater is designed with two independently controlled heating sections:

• A central zone with higher power density

• A peripheral zone that compensates for edge heat loss

This configuration offers three key advantages:

1. Eliminates Temperature Gradients

By actively heating the edges, the peripheral zone ensures that the entire print surface stays within the target temperature range. Whether you're printing a small detailed object or a full-bed model, the temperature remains consistent—minimizing the risk of warping or cracking caused by uneven cooling.

2. Improves Energy Efficiency and Heating Speed

Not every print uses the entire build volume. With a dual-zone system:

• Small prints can be made using only the central zone, reducing heat-up time and cutting energy consumption by 30-50%.

• Large prints utilize both zones, ensuring even heating without unnecessary energy waste.

This on-demand heating approach is both practical and eco-friendly.

3. Reduces Internal Stress in High-Shrinkage Materials

Materials like ABS and PC exhibit significant shrinkage during cooling (up to 7–10%). When the print bed has hot and cold spots, uneven cooling occurs, creating internal stress. This can lead to:

• Micro-cracks that weaken the model

• Visible cracks or splitting along temperature boundaries

A multi-zone heater allows both center and edges to cool uniformly, distributing stress evenly and preserving structural integrity.

Who Can Benefit from Multi-Zone Heaters?

This technology is particularly valuable for:

• Users printing with high-shrinkage materials (ABS, PC, Nylon)

• Those using large-format printers (like 500x500mm or above)

• Makers seeking higher success rates with large prints

• Professionals looking to improve energy efficiency in frequent printing

Upgrading to a multi-zone silicone heater is more than a minor improvement—it's a strategic enhancement that addresses fundamental thermal limitations in 3D printing. By delivering uniform heat, reducing stress, and saving energy, this technology helps both hobbyists and professionals achieve more reliable, consistent, and high-quality prints.

Whether you're building a custom printer or upgrading an existing one, consider a multi-zone heated bed—it might be the key to unlocking your next perfect print.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.