As drone applications expand from commercial filming to critical missions like infrastructure inspection and emergency response, one persistent physical limitation remains: battery performance in low temperatures. Lithium-based batteries, the standard for modern UAVs, suffer from severe efficiency loss and power delivery issues in cold environments. This isn't just an inconvenience—it can lead to mission failure, costly damage, or safety risks. An innovative and increasingly adopted solution is the integration of flexible polyimide heaters.

The electrochemical processes within LiPo and Li-ion batteries operate optimally within a narrow window, typically 15°C to 25°C (59°F to 77°F). When temperatures fall below 10°C (50°F), users experience:

● Significant Capacity Drop: Up to 30-50% reduced flight time.

● Increased Internal Resistance: Causes voltage to "sag" under high load (e.g., during ascent or maneuvering).

● Power Failure Risk: A sudden, unexpected loss of power mid-flight.

● Permanent Damage: Charging a cold battery can cause irreversible lithium plating.

Maintaining an optimal temperature is therefore not just about performance—it's about reliability and safety.

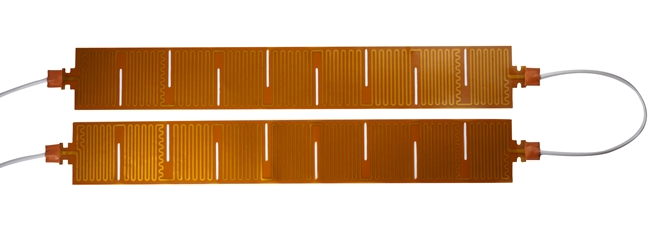

This technology represents a breakthrough in precision thermal management. Polyimide heaters are ultra-thin, lightweight, and conformable heating elements constructed in layers:

1. Polyimide Film Substrate: A high-temperature, flexible polymer film, often as thin as 0.025mm.

2. Etched Alloy Circuit: A resistive circuit (typically copper or nickel-chromium) etched into a precise pattern to ensure uniform heat distribution.

3. Electrical Insulation: Additional layers encapsulate the circuit for durability and electrical safety.

Unlike bulkier ceramic or silicone rubber heaters, polyimide heaters offer a unique combination of minimal thickness, flexibility, and high power density, making them ideal for integrating directly onto or within drone battery packs.

1. Ultra-Lightweight and Low-Profile:

Every gram counts in aerial vehicles. These heaters add negligible mass (often 1-5 grams) and virtually no rigid volume, preserving the drone's power-to-weight ratio and center of gravity.

2. Exceptional Flexibility and Durability:

The polyimide film can withstand bending, vibration, and mechanical stress—essential for the dynamic environment of a UAV in flight—without cracking or delaminating.

3. Rapid and Uniform Heating:

The etched circuit design ensures heat is spread evenly across the entire battery surface, preventing dangerous hot spots. They achieve target temperatures in seconds, enabling efficient pre-flight warming.

4. High Efficiency and Precision:

With excellent thermal coupling to the battery surface and the ability to pair with precise thermostats or controllers, these heaters maintain optimal temperature with minimal energy waste.

5. Design Versatility:

They can be custom-shaped to fit specific battery pack geometries, whether a flat surface or a more complex, curved form factor.

1. Thermal Interface: Use a thin layer of thermally conductive adhesive or epoxy to ensure optimal heat transfer from the heater to the battery casing.

2. Insulation: Mitigate heat loss to the cold ambient air during flight with lightweight insulating materials around the battery pack.

3. Reliable Control: Always integrate a calibrated thermostat or temperature sensor with a controller to cycle the heater and prevent overheating. Redundant safety cut-offs are recommended.

4. Weight and Balance: Account for the added components in your drone's overall weight and balance calculations.

5. Airworthiness: For commercial operators, ensure any modification complies with relevant aviation regulations and does not void critical warranties.

As this technology becomes more accessible and seamlessly integrated, expect thermally managed battery systems to transition from a professional accessory to a standard expectation for serious drone applications. For operators who cannot be grounded by the weather, investing in intelligent thermal management is the key to true operational resilience.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.