In the rapid evolution of new energy vehicles (NEVs), lithium-ion battery performance and longevity remain critical industry focus areas. Operating ideally within a 20°C to 35°C temperature window, lithium batteries in cold environments face reduced electrolyte mobility, slower charge transfer, diminished capacity, unstable power output, and potential lithium dendrite formation – all posing risks to battery life and safety. Consequently, efficient and reliable thermal management becomes essential. Among various heating technologies, Polyimide (PI) heaters are increasingly becoming the preferred choice for battery pack heating design due to their unique advantages.

I. Core Advantages of PI Heaters

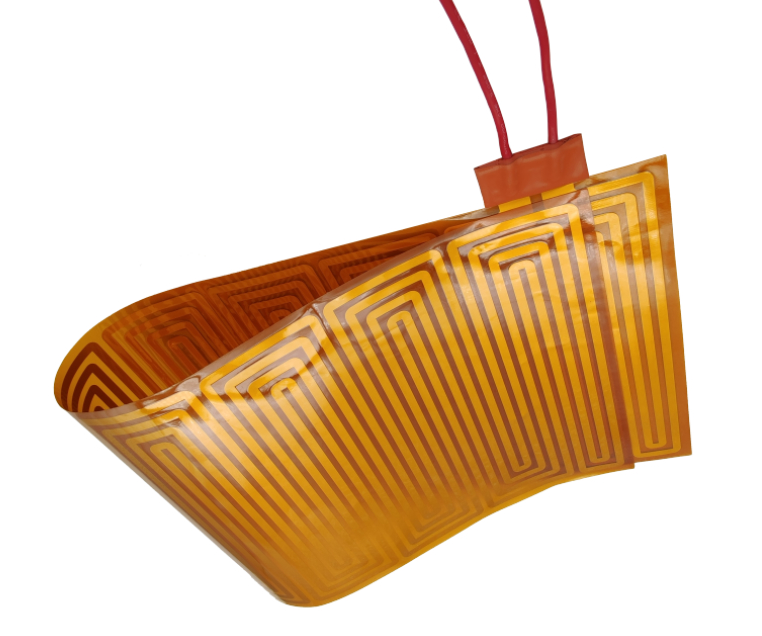

Ultra-Thin and Highly Flexible

PI heaters boast an exceptionally slim profile, with finished product thickness typically ranging from 0.15mm to 0.35mm. Their lightweight and flexible nature allows them to conform seamlessly to cell or module contours. With a minimum bending radius of approximately 0.8mm, they ensure intimate contact with battery surfaces—whether cylindrical, prismatic, or pouch cells—maximizing heat transfer efficiency and minimizing thermal resistance.

High Efficiency with Uniform Heating

Unlike traditional coil-based heating, PI heaters employ a planar heating approach that enables uniform surface power distribution, supporting power densities up to 7.8W/cm². Their low thermal inertia and rapid thermal response allow quick warm-up from low temperatures, effectively mitigating performance degradation caused by cold conditions.

Excellent Insulation and Enhanced Safety

Using polyimide film as the primary insulating material, PI heaters demonstrate outstanding dielectric strength and voltage resistance, routinely passing high-voltage tests exceeding 1500V. This robust insulation helps prevent leakage current and short-circuit risks, adding a critical layer of electrical safety to high-voltage battery systems.

High Customization for Diverse Battery Layouts

PI heaters can be tailored in voltage, power, dimensions, and shape to fit specific battery pack configurations. For example, a customized PI heating sheet designed for 18650 battery modules in collaboration with Huawei was precisely adapted to the voltage and dimensional requirements of the cell characteristics, optimizing overall energy efficiency.

II. Typical Installation Methods in Battery Packs

In practical battery module designs, PI heaters are commonly installed in three configurations:

Module Side Mounting: Applied to one or both sides of the module, ideal where space is limited;

Side + Bottom Combination: Heating both the side and base improves overall temperature uniformity;

Inter-Cell Gap Installation: Inserting heaters between cells enables three-dimensional, balanced heating.

Tests show that under the same total power, heating times across these three configurations are generally comparable and shorten as heating power increases. The combined "side + bottom" approach, in particular, helps reduce the average temperature of the heating film itself, enhancing both system safety and heating efficiency.

III. Beyond Heating: An Integrated Solution for Efficiency and Safety

PI heaters not only address cold-start challenges but also contribute to energy efficiency, lightweight design, and system integration. Their low thermal mass and fast response enable precise temperature control when integrated with the Battery Management System (BMS), avoiding overheating and energy waste. Moreover, their minimal thickness and weight hardly increase pack volume or mass, aligning perfectly with NEV goals for high energy density and compact layout.

As the new energy vehicle industry pushes for longer range, faster charging, and enhanced safety, PI heaters have emerged as an indispensable component in battery thermal management. With ongoing advancements in materials and control strategies, PI-based heating solutions are poised to support stable battery operation and vehicle safety across more extreme conditions and complex system architectures.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.