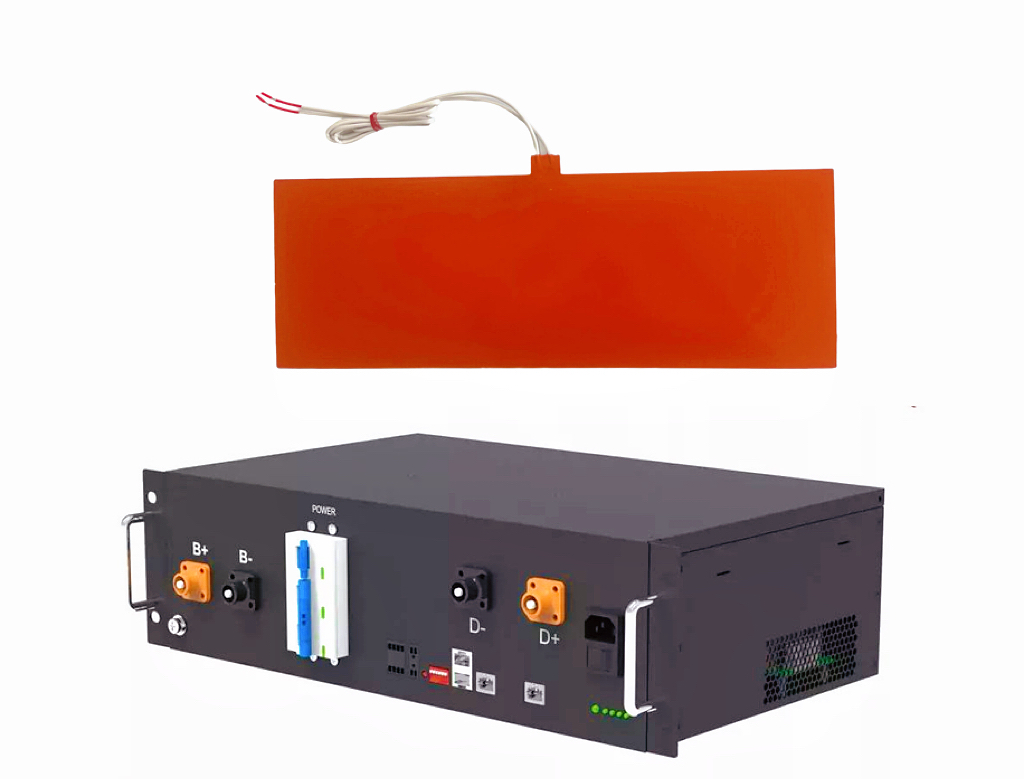

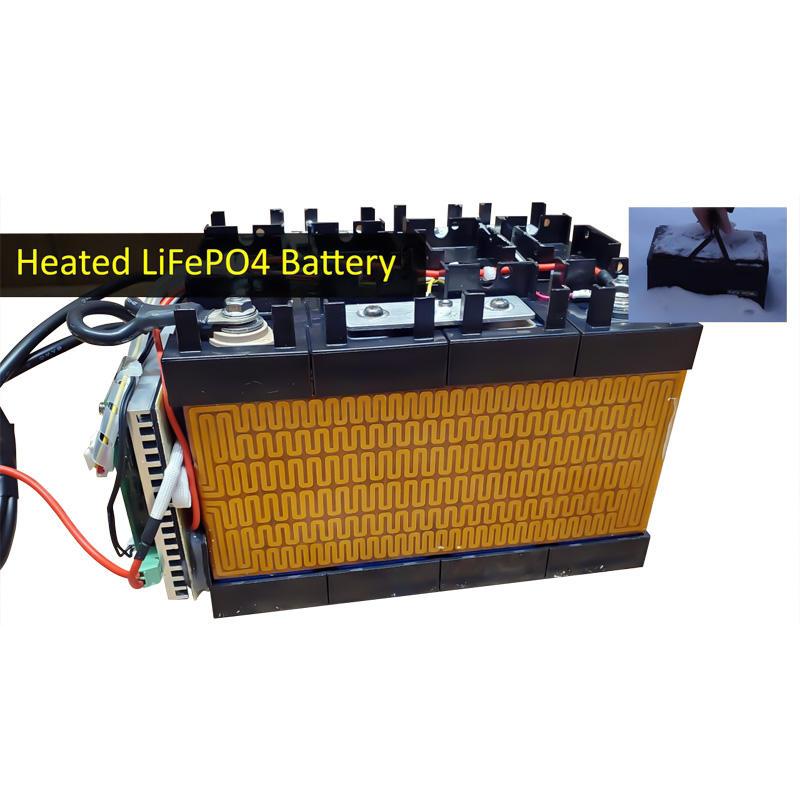

Silicone Heaters for LiFePO4 Battery Warming

How to Install a Heater on Automobile Rearview Mirror for Defogging?

Why Silicone Heaters Lead in Aerospace Battery Applications?

How Multi Zone Heaters Solve 3D Printing Warping and Cracking?

Why PI Heaters Are the Preferred Heating Solution for Battery Packs?

In the demanding world of aerospace technology, every component must meet the highest standards of reliability, efficiency, and durability. Among these critical components are heating systems for batteries, where silicone heating pads have become the preferred solution. But what makes them so well-suited for such advanced applications?

How Do Silicone Heating Pads Work?

Silicone heating pads consist of a thin, etched resistive foil securely embedded between layers of flexible silicone rubber. When an electric current flows through the foil, it generates heat, which is then evenly distributed through the silicone layer to the target surface—such as an aerospace battery—ensuring consistent and controlled warming.

These heaters are known for their dynamic performance, broad operational temperature range, and long service life. Below, we explore the key reasons why they are extensively used in aerospace battery systems.

Key Advantages of Silicone Heaters in Aerospace

1. Exceptional Durability

Silicone rubber is a robust and resilient material, capable of withstanding harsh conditions without degrading, making it ideal for long-term use in aerospace applications.

2. Wide Temperature Stability

These heating pads perform reliably across an extensive temperature spectrum, maintaining consistent operation whether in extreme cold or high-heat environments.

3. Resistance to Challenging Conditions

Built to endure thermal shock, moisture, oxidation, and chemical exposure, silicone heating pads offer dependable performance even in the most demanding settings.

4. High Dielectric Strength

With excellent electrical insulation properties, they help prevent short circuits and enhance the overall safety of the battery system.

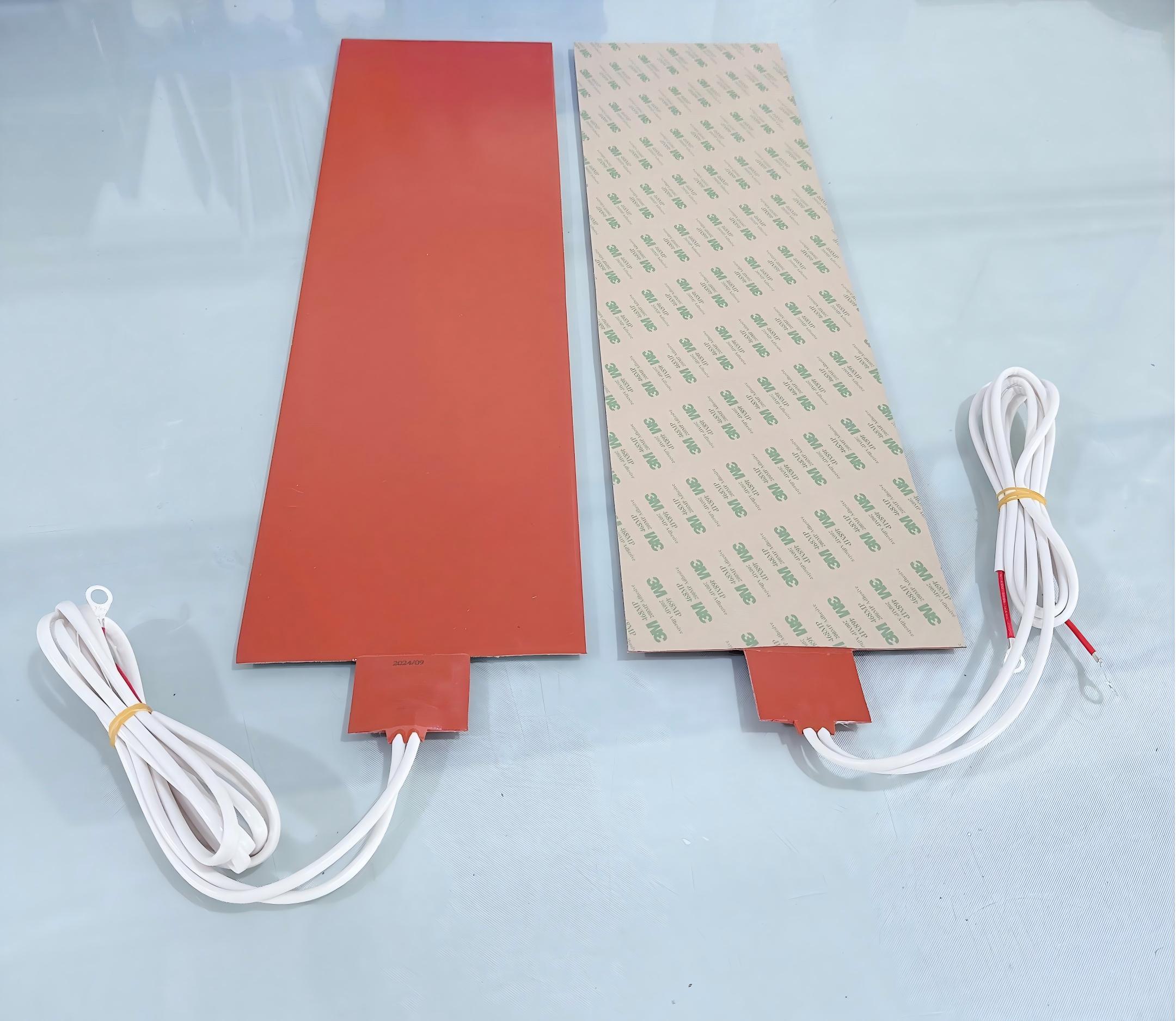

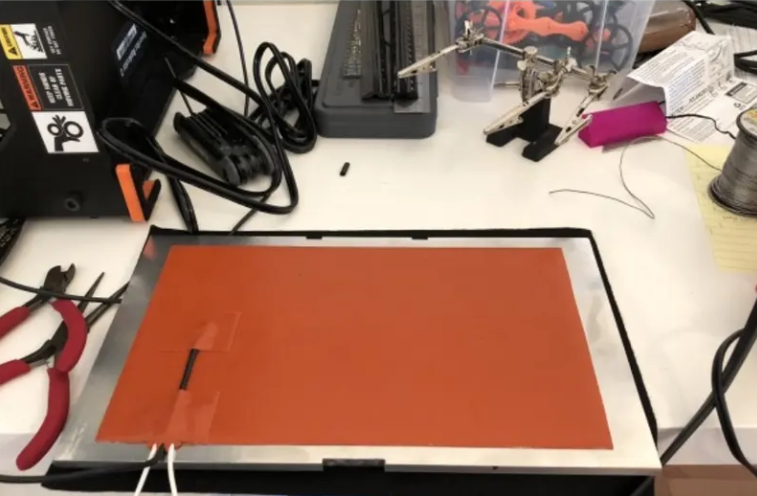

5. Conformability to Curved Surfaces

Their inherent flexibility allows them to be easily fitted to curved or irregular surfaces, ensuring full coverage and optimal thermal contact.

6. Compact and Space-Saving Design

Silicone heating pads can be customized to fit into tight or confined spaces, a crucial feature in space-constrained aerospace designs.

7. Rapid Thermal Response

Thanks to their thin and efficient construction, these heating pads offer quick heat-up times and fast thermal recovery, improving energy efficiency and response.

8. Uniform Heat Distribution

They provide even heat spread across the entire surface, avoiding hot spots and contributing to better battery performance and longevity.

9. Direct Vulcanization Capability

Silicone heating elements can be permanently bonded to most surfaces through vulcanization, maximizing heat transfer efficiency and mechanical stability.

10. High Customization Potential

From complex shapes and multiple heating zones to varied watt densities, dual voltage support, and integrated sensors—silicone heating pads can be tailored to meet precise application requirements.

Silicone heating pads bring a powerful combination of flexibility, resilience, and thermal efficiency to aerospace battery systems. Their ability to perform under pressure while adapting to specific design needs makes them an indispensable part of modern aviation and space technology. Whether for ensuring battery performance in low temperatures or enhancing system safety and longevity, silicone heaters continue to support innovation where it matters most.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.