PI Graphene Heating Film: Redefining Ultra-Thin Heating Solutions for Precision Applications

In today's rapidly evolving technological landscape, precision medical equipment, military instruments, and high-end electronic products place unprecedented demands on heating elements—requiring high efficiency, stability, flexibility, and reliability. Against this backdrop, the PI Graphene Heating Film has emerged as a critical bridge between advanced material science and practical industrial applications.

The Perfect Fusion of Polyimide and Graphene

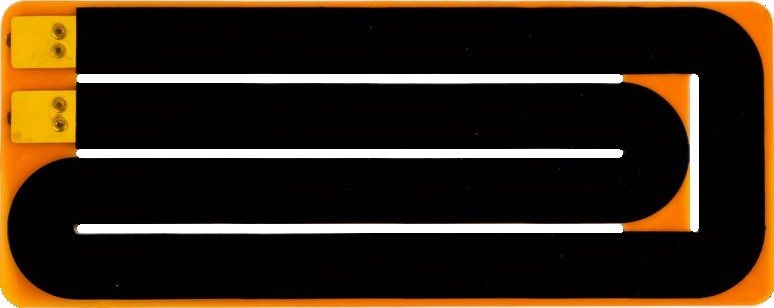

The core innovation of the PI Graphene Heating Film lies in its unique "sandwich" structural design. It employs polyimide (PI) film as the outer insulating layer—a material often referred to as the "golden film" for its exceptional high-temperature resistance, mechanical strength, and electrical insulation properties. This polymer maintains stable physical and chemical performance across an extreme temperature range of -269°C to 400°C.

The internal heating element utilizes advanced nickel-chromium alloy etching technology or graphene conductive layers, forming uniform circuit patterns through precise etching processes. This design not only achieves an ultra-thin profile (thickness of only 0.1–0.4 mm) but also ensures even heat distribution across the surface, eliminating the localized overheating issues common in traditional heating wires.

Technical Parameters Demonstrating Exceptional Performance

Temperature Range: Long-term operation up to 160°C, short-term tolerance up to 250°C

Ultra-Thin Design: 0.1–0.4 mm thickness, adding minimal volume to devices

Rapid Response: Reaches target temperature in seconds

Uniform Heating: Surface temperature variation controlled within ±2°C

High Energy Efficiency: Over 98% electro-thermal conversion efficiency

Safety and Reliability: Withstands breakdown voltages exceeding 3000V

Multi-Domain Application Scenarios

Leveraging its ultra-thin, flexible, efficient, and safe characteristics, the PI Graphene Heating Film demonstrates broad application potential across various high-tech fields:

Healthcare Sector: Maintains constant temperature environments in in vitro diagnostic equipment, serves as the core heating element in physiotherapy devices, and provides precise temperature control during blood and pharmaceutical transport.

Military and Aerospace Applications: Offers reliable thermal insulation for spacecraft instruments in vacuum and low-temperature conditions, integrates into soldier combat gear for low-power heating, and protects precision optical equipment from fogging and frost.

Consumer Electronics: Addresses performance issues in flexible display devices under low temperatures, extends drone battery life in cold environments, and provides ultra-thin, efficient heating solutions for wearable smart devices.

Six Core Advantages

Ultra-Thin Flexibility: 0.1 mm thickness, bendable to a 3 mm radius

Corrosion Resistance: Withstands most chemical solvents

Temperature Uniformity: Achieves true surface-level even heating

Rapid Response: Heating time reduced by over 70% compared to traditional heaters

Long Service Life: Continuous operation lifespan exceeding 10,000 hours

Energy Efficiency and Environmental Friendliness: High electro-thermal conversion minimizes energy waste

The PI Graphene Heating Film represents more than just a product—it embodies an innovative philosophy of solving traditional technical limitations through material advancements and structural optimization. In an era of device miniaturization, this heating element, with a thickness of less than half a millimeter, is redefining the concept of "heating" across critical sectors such as military, medical, and electronics.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.