Our flexible film heaters are high-performance but need careful handling. To help you avoid mistakes and extend their lifespan, we’ve put together this practical pre-installation guide—save it for later.

▶ Wiring & Environment: 2 Critical Don'ts

1. Never leave leads hanging loose

Secure the leads firmly during installation. Loose leads can get pulled, causing internal damage to the heater (which may render it useless immediately).

2. Keep away from hazardous environments

Do NOT immerse the heater in liquids, or expose it to steam/corrosive gases—these will damage the heater quickly.

▶ Voltage & Operation: 4 Must-Follows

3. Don't exceed the rated voltage

Always use the specified/rated voltage. Overvoltage will burn out the heater instantly!

4. No "violent handling" of the heater

Cutting, drilling, disassembling, or contact with sharp objects is strictly forbidden. Never attempt to repair a damaged heater—it’s unsafe and irreparable.

5. No unattended operation

Do not run the heater when no one is monitoring it, unless adequate safety control devices are installed.

6. Don't stack heaters

Overlapping installation will cause overheating and drastically reduce the heater’s lifespan.

▶ Installation Details: 5 Tips That Determine Longevity

7. Bend with limits

The heater can be curved around surfaces, but the minimum bending radius must not be less than 0.5mm—exceeding this will damage internal structures.

8. Use blunt connection angles

When joining two contact surfaces, use blunt angles to avoid puncturing or tearing the heater’s surface.

9. Cooling is key for high-power heaters

● Power density > 0.4W/cm²: Must be connected to a heat sink (do NOT install it independently in air);

● Power density > 0.8W/cm²: Additional temperature control is required, and the heater must be installed with a metal plate + recommended silicone/silicone adhesive;

● Power density up to 10W/cm²: Ensure full contact with no air bubbles between the heater and the surface—otherwise, failures will occur quickly!

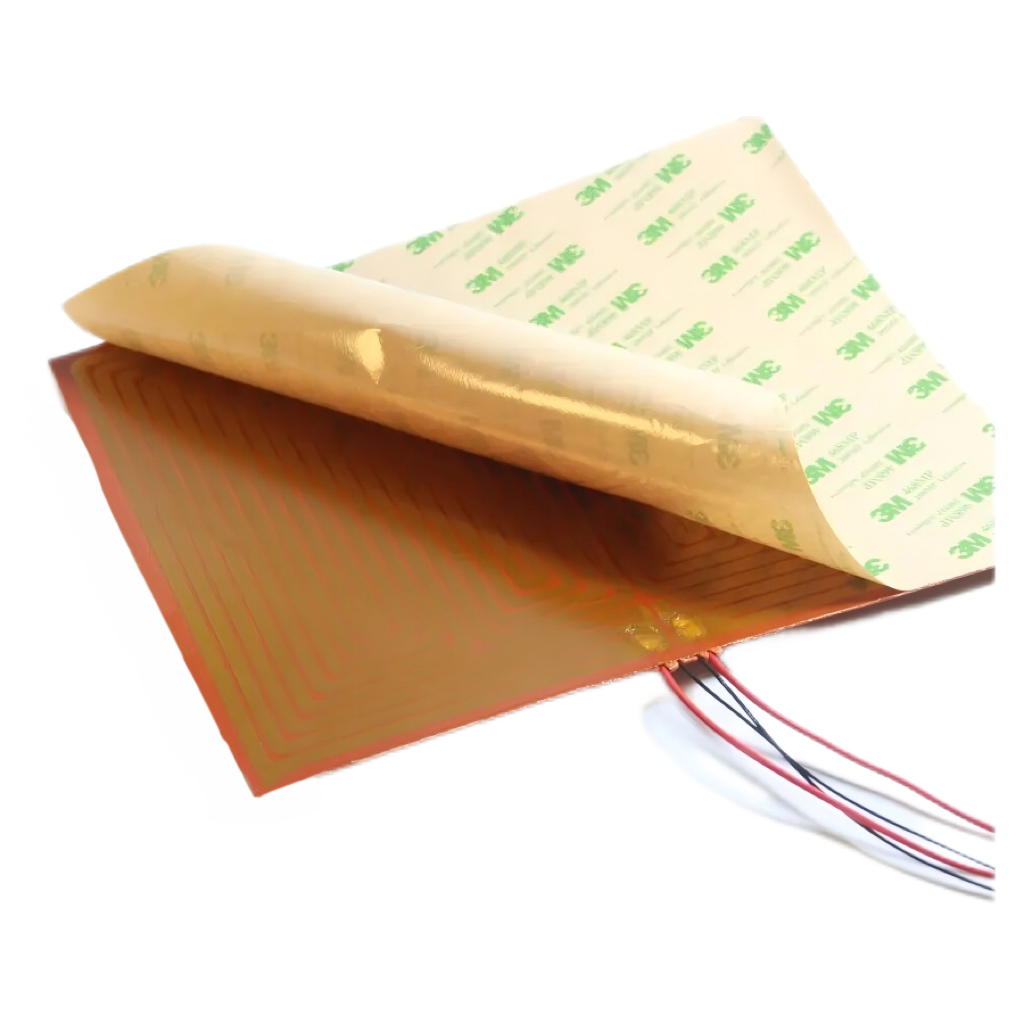

10. Use reliable fastening methods

Mechanical clamping, factory-supplied PSA (pressure-sensitive adhesive), or conductive epoxy can be used. Note:

● Ensure full contact (no air bubbles) between the heater and the surface;

● Keep terminals/leads away from metal plates/conductive materials to avoid short circuits!

11. Do Not Use Heaters with Air Bubbles

If air bubbles appear in the heater (after installation), stop using it immediately and replace it with a new heater. Do not attempt to repair it. Bubbles indicate internal damage, likely from overvoltage or improper installation, which creates hotspots and poses a safety risk.

▶ Disassembly & Final Step: 1 Last Reminder

12. Wait for cooling before disassembly

Before removing the heater, turn off the power and wait for all components to cool completely—this prevents burns and component damage.

By following these details, the heater will operate safely and last much longer! Feel free to reach out at sales@hrx-heaters.com with any installation questions.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.