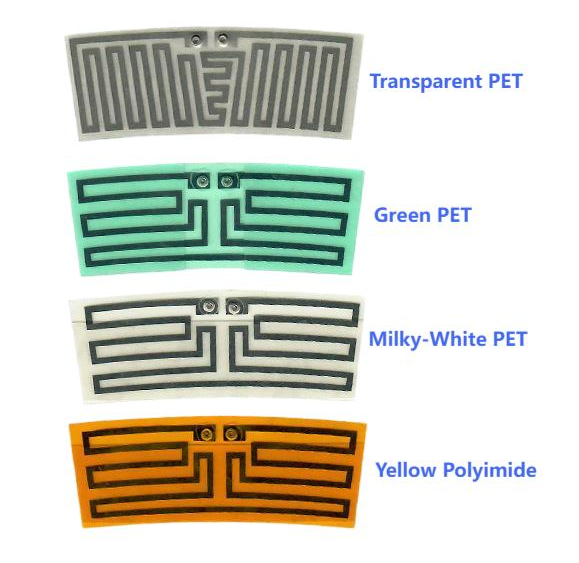

Today, we're diving into the world of flexible heating solutions, focusing on three types of PET heating films (transparent, milky - white, green) and the polyimide heater. Let's break down their differences in materials, performance, and applications.

1. Material Composition Basics

PET Heating Films

All three PET heating films share the same base material—PET, a widely - used thermoplastic polymer.

Transparent PET: It's close to the pure form of PET, with little to no color - adding pigments. This keeps its natural transparency.

Milky - White PET: Contains titanium dioxide or similar white pigments. These pigments scatter light, giving it that opaque, milky look.

Green PET: Gets its color from green color masterbatches (like phthalocyanine green). Sometimes, it may have additional additives for UV resistance or other functions.

Polyimide Heater

The yellow polyimide heater is made from polyimide, a high - performance polymer known for its excellent thermal and chemical stability. Unlike PET, polyimide has a distinct molecular structure that gives it unique properties.

2. Performance Comparison

Transparency and Light Interaction

Transparent PET: Allows most light to pass through. Perfect for applications where you need to see through the heater, like in some display - related heating or observation windows.

Milky - White PET: Has strong light scattering. It blocks light well, which is great for hiding internal components and reducing heat absorption from external light sources.

Green PET: The light transmittance depends on the pigment concentration. It offers a middle - ground, and the green color can also help blend into certain environments (like agricultural setups).

Polyimide Heater: Standard color is Yellow (also have white, black colors). It doesn't focus on light - related properties as much as PET films; instead, it prioritizes thermal and mechanical performance.

Thermal and Mechanical Properties

PET Heating Films: Generally, PET has good thermal stability for moderate - temperature applications (usually up to around 80-100°C). The mechanical strength is decent, making it flexible and suitable for curved surfaces.

Polyimide Heater: Polyimide can handle much higher temperatures (often above 130°C). It also has outstanding mechanical toughness and chemical resistance, which is why it's a go - to for harsh environments, like in aerospace or high - end electronics.

Insulation and Weather Resistance

PET Films: The insulation performance is based on the PET material. For outdoor use, the green PET might have an edge with added UV - resistant additives, while the transparent one may need extra protection.

Polyimide Heater: Polyimide inherently has good insulation and can withstand harsh chemicals and weather conditions, but it might be overkill for simple, low - cost applications.

3. Application Scenarios

Transparent PET Heating Film

Use Cases: Ideal for applications where visibility is key. Think of defogging films for vehicle windows (where you still want to see outside clearly), or small heating elements in display devices where the internal structure needs monitoring.

Example: In a laboratory, a transparent PET heating film could be used on a glass - walled reaction chamber to maintain temperature while allowing researchers to observe the process.

Milky - White PET Heating Film

Use Cases: Perfect for hiding internal wiring or components. It's great for consumer products like heated cushions (where you don’t want to see the heating elements) or backlight units in electronics (to enhance light reflection).

Example: In a laptop's keyboard heating module, the milky - white PET can evenly distribute heat and keep the internal wiring hidden for a clean look.

Green PET Heating Film

Use Cases: Suited for applications where environmental blending or a “safe” visual cue is needed. Agricultural settings (like greenhouse heating films that blend with plants) or medical devices (where green implies safety and hygiene) are good fits.

Example: A green PET heating film could be used in a medical warming tray, giving patients a sense of safety while keeping the temperature of medical supplies stable.

Polyimide Heater

Use Cases: When high - temperature resistance and durability are non - negotiable. Aerospace components (like satellite equipment heating), high - end industrial machinery, or flexible circuits in harsh environments are typical applications.

Example: In a jet engine's sensor module, the polyimide heater can withstand extreme temperatures and vibrations to keep the sensors at optimal operating conditions.

4. Choosing the Right One

For Cost - Effective, Moderate - Temp, and Aesthetic Needs: Go for PET heating films. Choose transparent for visibility, milky - white for hiding elements, and green for environmental or safety cues.

For High - Temp, Harsh Environments: The polyimide heater is your best bet, even though it might come with a higher cost.

In conclusion, whether you pick a PET heating film or the polyimide heater depends on your specific application requirements—temperature range, environmental conditions, visual needs, and budget. Each has its own strengths, and understanding these differences will help you make the perfect choice for your next project.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.