In industrial processing, ensuring smooth material flow within conical hoppers, bins, or funnels is a constant challenge. Enter silicone rubber heaters for conical hoppers – custom - engineered flexible solutions designed to wrap snugly around tapered equipment. These heaters tackle common flow disruptions caused by material cooling, moisture buildup, or bridging, especially in the high - pressure, steep cone sections where blockages frequently occur.

Custom Designed for Precision Performance

These silicone heaters are built to fit the unique geometry of conical hoppers like a glove. Unlike one - size - fits - all options, their custom design ensures efficient heat transfer, directly addressing the root causes of flow issues. By keeping materials at optimal temperatures and preventing unwanted bridging, they help maintain seamless operations and cut down on costly downtime.

Key Specifications: Engineered for Industrial Needs

Thickness: Ranging from 1.5mm to 3.0mm (standard), striking a balance between flexibility for easy wrapping and durability for long - term use.

Operating Temperature: Capable of handling extreme conditions, from - 60°C to 200°C, making them adaptable to diverse industrial environments and material requirements.

Voltage: Available in 12V, 24V, 120V, 240V, with customizable options to match your existing power systems.

Power Rating: Spanning 100W–2000W (based on shelf area), allowing precise heat output tailored to your hopper's size and material handling needs.

Lead Wires: Offered with silicone or PTFE insulation and various lengths, accommodating different installation setups and spatial constraints.

Thermostat Options: Choose between dial and digital thermostats for straightforward temperature control, aligning with your operational demands.

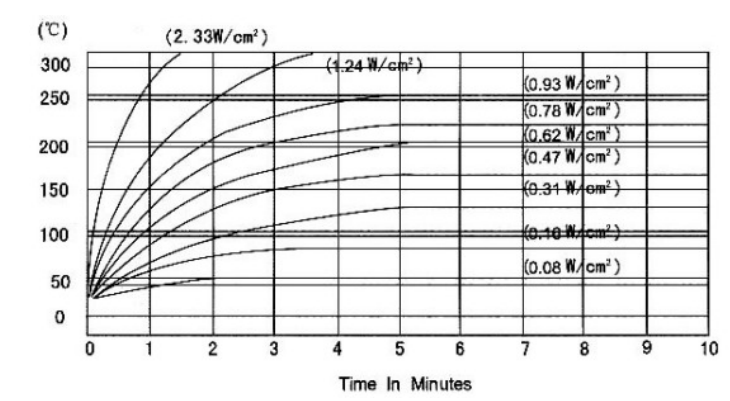

Decoding Thermal Performance: Insights from Data

Take a look at the accompanying thermal graph. It maps temperature changes over time for different power densities (e.g., 2.33W/cm², 2.24W/cm², etc.). This data shows how quickly and effectively the silicone rubber heater can warm materials, helping you pick the right power settings for consistent material flow. Higher power densities, for example, mean faster temperature rises – perfect for swiftly tackling cooling - related blockages.

Industry - Specific Impact: Where They Shine

These versatile heaters have become industry essentials, proving their value across key sectors:

Plastics: Stop PET/PE pellets from crystallizing in feed hoppers, preserving material quality and keeping production lines running smoothly.

Food Processing: Ensure sugar, starch, and powdered dairy flow freely, maintaining production continuity and product integrity.

Pharma: Keep hygroscopic APIs and excipients at controlled humidity levels, safeguarding the stability of drug formulations.

Chemicals: Prevent caking in urea, fertilizers, and polymer powders, reducing waste and boosting process reliability.

Silicone rubber heaters for conical hoppers are more than just equipment – they're a strategic investment in operational efficiency. By solving material flow headaches, they help industries maintain productivity, product quality, and process consistency. Ready to transform how your conical hoppers perform? Explore integrating these heaters and experience a new level of streamlined, reliable material handling.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.