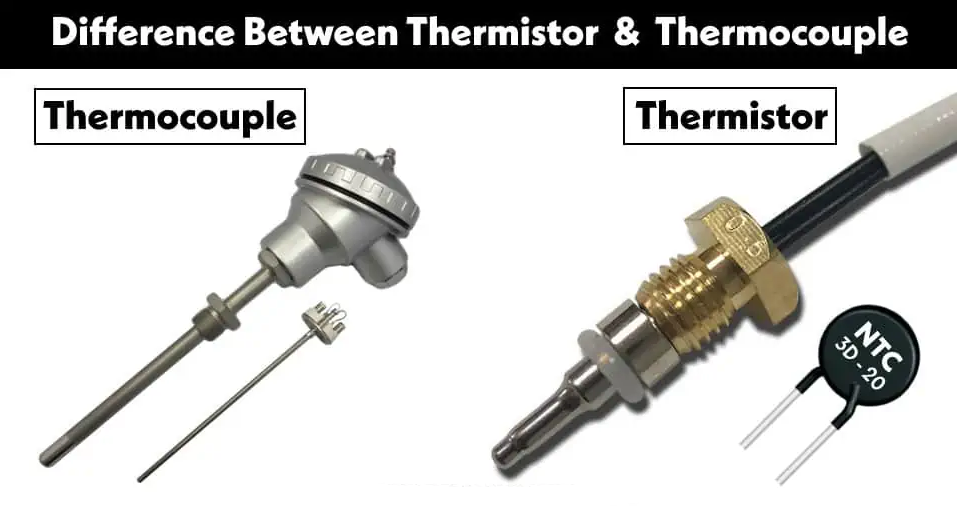

Temperature sensors are essential tools across various industries, enabling accurate monitoring and control of processes. Among the most common types are thermistors and thermocouples. While both serve the same fundamental purpose—measuring temperature—their underlying principles, characteristics, and applications differ significantly. Let’s explore the key distinctions to help you make an informed choice for your application.

Thermistors are resistive devices whose resistance changes with temperature. They are broadly categorized into two types:

1. Negative Temperature Coefficient (NTC) Thermistors: Resistance decreases as temperature rises.

2. Positive Temperature Coefficient (PTC) Thermistors: Resistance increases as temperature rises.

Thermistors are made from semiconductor materials, allowing them to provide highly sensitive and precise temperature readings within a defined range.

Thermocouples operate on a completely different principle, utilizing the Seebeck Effect. This phenomenon occurs when two dissimilar metals are joined at two points, creating a circuit. A temperature difference between these junctions generates a voltage, which is proportional to the temperature gradient. By measuring this voltage, the temperature can be determined.

2. Thermocouples: Offer a much broader range, from -200°C to over 2000°C, making them suitable for extreme environments.

Accuracy

1. Thermistors: Provide excellent accuracy in their operational range, ideal for precise temperature control.

2. Thermocouples: Have lower accuracy compared to thermistors but are better suited for applications requiring a wide temperature span.

Response Time

1. Thermistors: Have a rapid response to temperature changes due to their compact size and thermal properties.

2. Thermocouples: Also respond quickly, particularly in dynamic or fluctuating conditions.

Durability and Environment

1. Thermistors: Best suited for stable, controlled environments.

2. Thermocouples: Built to withstand extreme conditions such as high temperatures, corrosive environments, or mechanical stress.

Applications

1. Thermistors: Commonly found in household appliances, temperature compensation circuits, and medical devices.

2. Thermocouples: Widely used in industrial furnaces, aviation, automotive systems, and scientific research due to their high-temperature capability.

Selecting between a thermistor and a thermocouple depends on the specific needs of your application:

· For precise measurements within a limited temperature range, thermistors are the ideal choice.

· For extreme temperatures or rugged environments, thermocouples are indispensable.

Always consider factors such as temperature range, required accuracy, response time, and environmental conditions when making your decision.

Both thermistors and thermocouples are indispensable tools in temperature measurement. By understanding their unique properties and strengths, you can choose the right sensor for your needs and optimize your application’s performance. Whether it’s the precision of thermistors or the versatility of thermocouples, each has a critical role to play in modern technology.

Related product links

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.