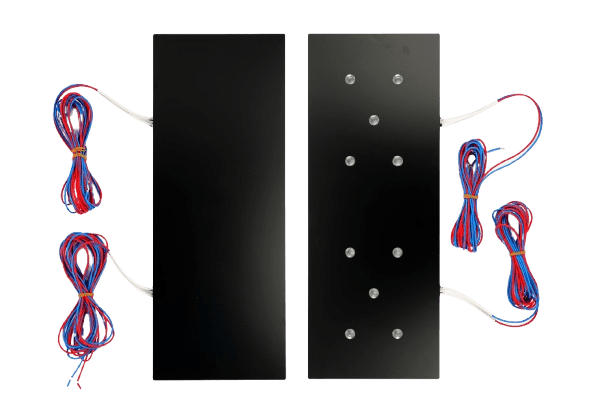

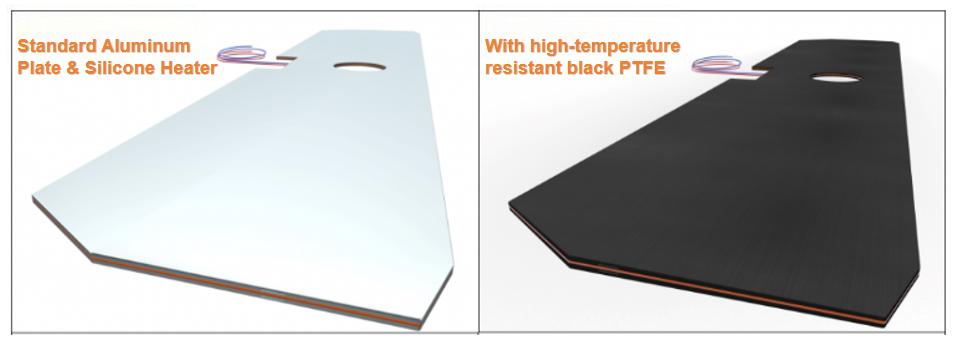

The battery drying & formation equipment heating plate is composed of an aluminum plate as the heat dissipation body, thermally conductive silicone cloth as the insulating layer, and metal foil as the conductive heating element, all bonded through high-temperature thermal lamination.

Using aluminum plate and thermally conductive silicone cloth as the base materials, this heating plate is lightweight, wear-resistant, and offers excellent thermal conductivity, vibration resistance, high voltage resistance, heat transfer efficiency, and mechanical strength.

It is widely applicable in formation machinery, drying equipment, automated tunnel furnaces, precision instruments, medical devices, and new energy battery pack preheating. With the rapid adoption of new energy vehicles, power batteries—as the core component—directly impact the technical performance and safety of these vehicles.

In recent years, research on power batteries has largely focused on improving anode and cathode materials, studying internal chemical reactions during charging and discharging, and optimizing key manufacturing processes such as drying. The fully automatic vacuum drying system—tunnel type—utilizes the 1450 battery drying/formation equipment heating plate, which takes full advantage of the high thermal conductivity of the aluminum plate heating panel. With high heat conversion efficiency, a flat surface, scratch resistance, and superior voltage resistance, it enables large-scale production with a capacity increase of 500% to 1000%.

The heating plate provides exceptional temperature uniformity. The entire preparation process takes place in a high-vacuum environment, where high temperature consistency effectively removes moisture, gas, and impurities inside the battery cell. This helps reduce internal resistance, improve consistency, enhance high-frequency characteristics, and increase energy density—significantly boosting the consistency and cycle life of battery cells and modules.

The heating plate delivers outstanding thermal conductivity, effectively transferring heat to the target area. The silicone layer offers excellent vibration resistance, waterproofing, high-temperature tolerance, and high voltage resistance, providing unparalleled safety advantages.

Key Features:

1. Flexible thickness: 1.0–10mm or thicker, with ultra-long dimensions available.

2. Sandblasted aluminum surface for high cleanliness.

3. Fast heating speed, uniform temperature distribution, minimal panel temperature variation, and heat conversion efficiency up to 99%.

4. Rigid plate design, optionally equipped with 3M double-sided adhesive or screw-fastening installation.

5. High insulation performance, withstands up to 2500V AC voltage testing, exceeding national safety standards.

6. Customizable design to meet specific client requirements.

7. Vibration-resistant, pressure-resistant, and wear-resistant material properties.

8. Durable metal heating element with stable power output.

The aluminum heating plate stands out for its design flexibility, excellent insulation and voltage resistance, strong mechanical strength, even heat distribution, and high conversion efficiency. It is safe, reliable, and long-lasting, holding an irreplaceable position across industries such as machinery, aerospace, military, and new energy applications.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.