How Polyimide Heaters Keep Lenses Crystal Clear in Extreme Cold

Thermal Fuses: Small but Mighty Protectors of Your Electronics

What Are the Key Differences Between Silicone and Other Heating Materials?

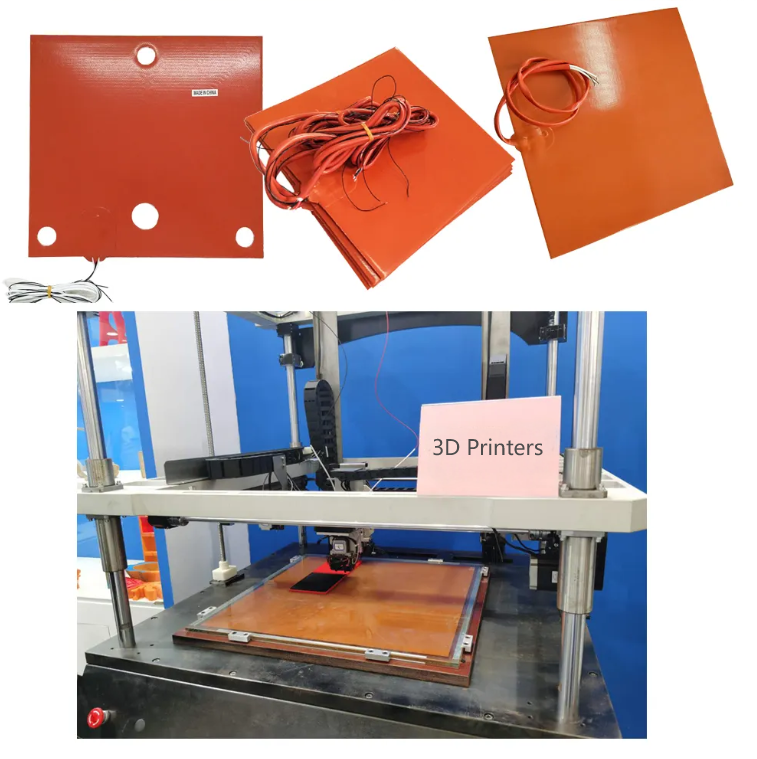

Why Silicone Heaters Are Better Than Polyimide for 3D Printer Heated Beds?

Why Most Flexible Heaters Use Adhesive Backing?

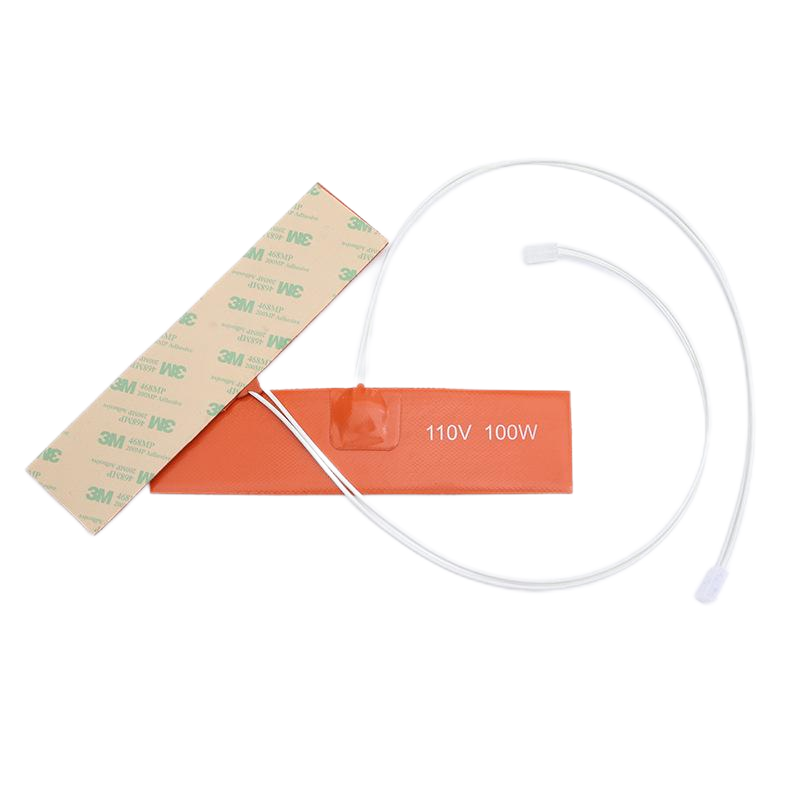

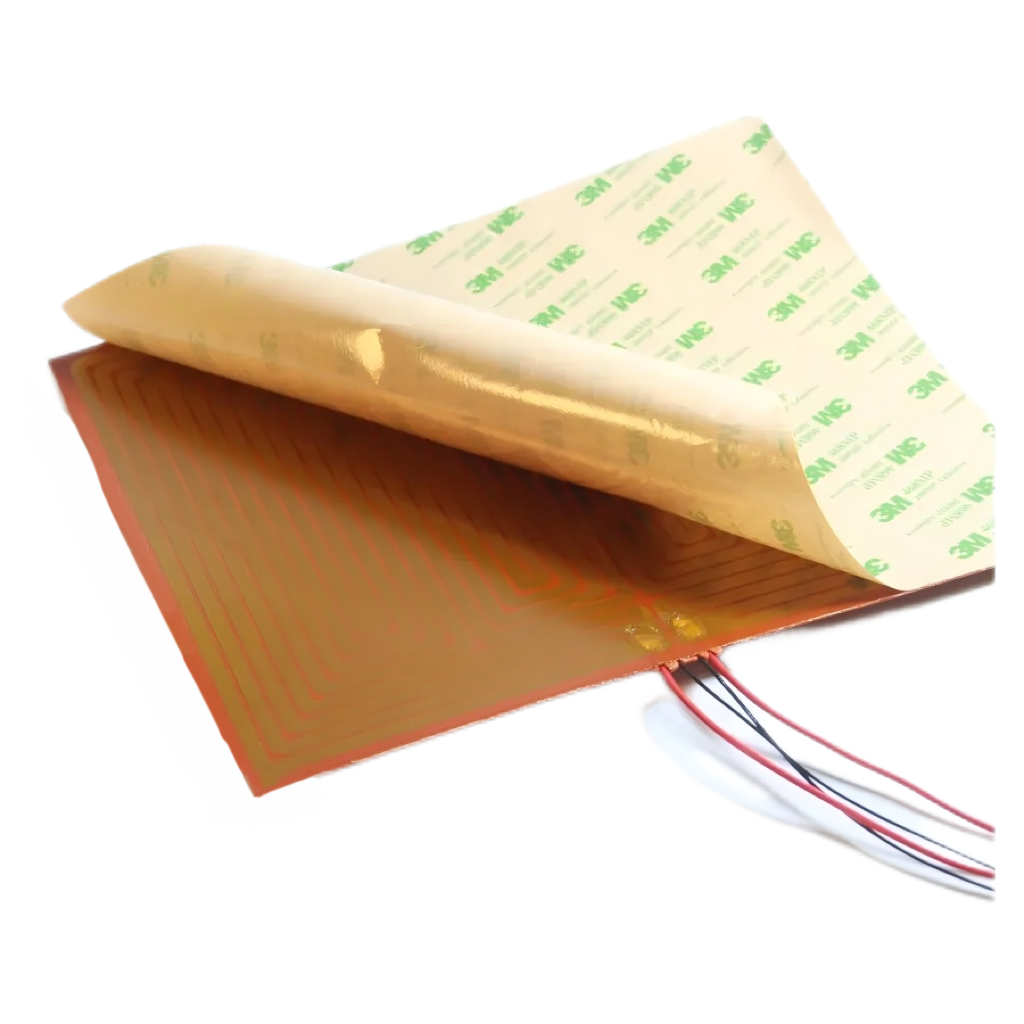

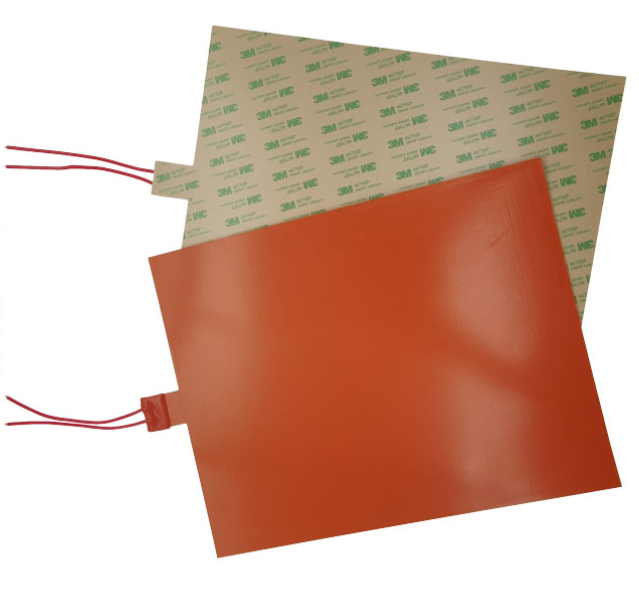

As a manufacturer of flexible heaters (including silicone rubber pads and polyimide heaters), you might wonder why many designs incorporate adhesive backing (e.g., 3M PSA). The answer lies in simplified installation, enhanced thermal efficiency, and improved reliability across diverse applications. Below, we break down the key advantages:

No mechanical fasteners required – Unlike traditional heaters needing clamps or screws, adhesive-backed versions bond directly to surfaces, cutting labor costs and speeding up assembly. Ideal for mass production or tight spaces (e.g., medical devices, 3D printers, PCBs).

Conforms to complex shapes – Both silicone heaters (flexible) and polyimide heaters (thin-film) adhere seamlessly to curved or irregular surfaces (pipes, machinery), eliminating gaps that reduce heating efficiency.

Eliminates air gaps – Mechanical fasteners create air pockets (thermal conductivity: ~0.026 W/m·K), while adhesive fills micro-imperfections for optimal conduction on metals, plastics, or glass.

Minimal thermal resistance – Adhesive layers (0.05–0.2mm thick) balance strong adhesion and efficient heat spread, critical for precision applications (lab equipment, semiconductor processes).

Stays secure under stress – In automotive, aerospace, or robotics, vibrations can loosen mounts. High-performance adhesives (acrylic, epoxy-modified) endure up to 150°C and shocks, preventing detachment.

Environmental protection – Silicone-based adhesives add waterproofing and corrosion resistance, ideal for outdoor or humid environments (e.g., solar panels, EV batteries).

Enhanced insulation – While silicone heaters are inherently insulating, adhesives with ceramic/fiberglass reinforcement suit high-voltage uses (e.g., EV heating). Polyimide’s inherent dielectric strength pairs well with adhesives for electronics.

Removable options – Low-residue adhesives allow temporary removal for maintenance (e.g., optical sensors, industrial molds) without surface damage.

Temperature limits: Standard adhesives work up to ~150°C; Special high-temperature adhesive tape can operate at 200℃ for a long time and 270℃ for a short period. Make the right choice based on the product requirements.

Surface prep: Clean (alcohol-wiped), smooth surfaces ensure maximum adhesion.

Cost vs. benefit: Slightly higher upfront cost offsets long-term savings in installation and maintenance.

Adhesive-backed flexible heaters (silicone or polyimide) deliver faster installation, better heat transfer, and long-term reliability—making them essential for industries prioritizing precision, efficiency, and durability.

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.