Silicone heaters serve as a cornerstone in 3D printing systems, delivering critical heating solutions for both desktop and industrial-grade printers. Their unique combination of flexibility, temperature control, and durability makes them indispensable for processing thermoplastic materials like ABS, PLA, PETG, and TPU. Below is a detailed overview of their usage in the 3D printing industry:

1. Material & Printer Compatibility

Silicone heaters exhibit exceptional compatibility with 3D printing's core materials and equipment designs. Constructed from fiberglass-reinforced silicone rubber with nickel-chromium (Ni-Cr) alloy heating elements , they resist chemical interactions with common thermoplastics, eliminating material degradation risks. Their flexibility allows seamless conformity to flat build plates—where polyimide heaters (better for curved surfaces) fall short —making them ideal for FDM (Fused Deposition Modeling) printers, the most widely used 3D printing technology. They support voltages from 12V to 240V and integrate with popular printer models like RepRap and Davinci V2 , with customizable sizes (15mm to 10,000mm in length) to fit any build plate dimension.

2. Uniform Heating for Print Quality

Uniform heat distribution is critical to preventing print defects like warping or layer separation, and silicone heaters excel in this area. Embedded etched foil or wire-wound elements ensure consistent surface temperatures across the entire build plate , with minimal variance even for large 250×250mm pads . This uniformity is especially vital for materials like ABS, which require stable bed temperatures (90–110°C) to adhere properly . Unlike traditional metal heaters, silicone pads transfer heat efficiently to aluminum or glass build plates via direct contact, supported by optional 3M adhesive backings for secure thermal coupling.

3. Precise Temperature Control

Silicone heaters enable granular temperature regulation, a must for matching material-specific requirements. Most integrate NTC 100K thermistors (with β values around 3950K) that feed real-time data to the printer’s PID controller, maintaining temperatures within ±1°C . They operate across a broad range: from -40°C (for cold-environment printing) to 200°C (suitable for high-temperature filaments like PETG) , with imported silicone variants reaching up to 250°C . This precision eliminates overheating risks and ensures consistent layer adhesion, even for long-duration prints.

4. Energy Efficiency

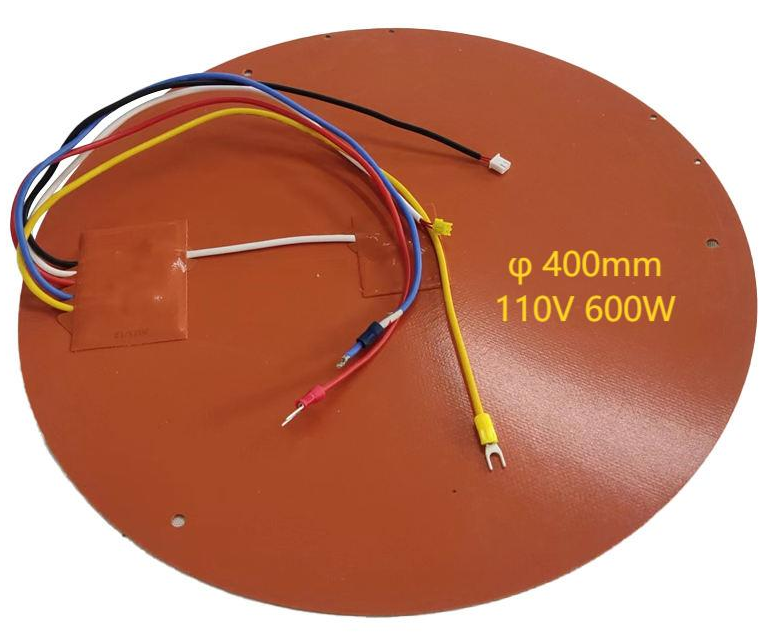

Silicone heaters are engineered for low energy consumption without sacrificing performance. Their thin profile (1.5–3mm) and high heat conversion efficiency minimize warm-up times—reaching target temperatures (60–150°C) in minutes —while maintaining steady heat with minimal power draw. A 120×120mm, 12V pad uses just 120W , and even large 600W pads for industrial printers optimize energy use via PID control . This efficiency reduces operational costs for both hobbyists and manufacturers, especially for high-volume printing.

5. Safety & Durability

Designed for rigorous 3D printing environments, silicone heaters prioritize longevity and user safety. Their silicone rubber insulation is moisture-proof, chemical-resistant, and withstands repeated heating-cooling cycles without degradation , offering a service life far exceeding traditional heating elements. Built-in safeguards include thermal fuses and bimetal thermostats that cut power if temperatures exceed safe limits, while electrical insulation (reinforced by fiberglass layers ) prevents short circuits. They also meet international safety standards (CE, ROHS, ISO) , ensuring compliance for commercial use.

6. Specialized Applications in 3D Printing

Beyond standard build plate heating, silicone heaters support advanced 3D printing needs:

Enclosure Heating: Custom-shaped pads warm printer enclosures, maintaining stable ambient temperatures for ABS and polycarbonate prints.

Nozzle Auxiliary Heating: Small silicone strips preheat print nozzles, reducing material oozing during setup.

Prototyping & Testing: In R&D labs, they heat filament samples to test thermal stability or layer adhesion under controlled conditions, leveraging their precise temperature control for reliable data .

Silicone heaters are the gold standard for 3D printing heating solutions, combining material compatibility, uniform heat distribution, precise control, energy efficiency, and robust safety. Whether for hobbyist desktop printers or industrial manufacturing lines, they address the core challenges of thermoplastic printing—from adhesion to defect prevention—while offering customization to fit diverse equipment needs. For anyone prioritizing print quality and operational reliability, silicone heaters are an indispensable 3D printing component.

IHRX can supplies all kinds of heaters customized for your business, Please contact us by follow ways

We offer a wide variety of high-efficiency heaters and heating element.Such as polyimide/kapton heaters,silicone rubber heaters,PET transparent heaters, thick film heaters,PTC heaters, mica heaters,epoxy resin heaters and graphene heating film.